|

| Designers at work in 1961. Standing by the scale model's left front fender is Dick Teague, an automobile designer at American Motors Corporation (AMC). |

Automotive design is the process of developing the appearance (and to some extent the ergonomics) of motor vehicles - including automobiles, motorcycles, trucks, buses, coaches, and vans.

The functional design and development of a modern motor vehicle is typically done by a large team from many different disciplines also included within automotive engineering, however, design roles are not associated with requirements for professional- or chartered-engineer qualifications. Automotive design in this context focuses primarily on developing the visual appearance or aesthetics of vehicles, while also becoming involved in the creation of product concepts. Automotive design as a professional vocation is practiced by designers who may have an art background and a degree in industrial design or in transportation design. For the terminology used in the field, see the glossary of automotive design.

|

| The 2003 Bertone Birusa concept car on display at the Geneva Motor Show. In the background are some concept sketches. |

Design elements

The task of the design team is usually split into three main aspects: exterior design, interior design, and color and trim design. Graphic design is also an aspect of automotive design; this is generally shared amongst the design team as the lead designer sees fit. The design focuses not only on the isolated outer shape of automobile parts, but concentrates on the combination of form and function, starting from the vehicle package. The aesthetic value will need to correspond to ergonomic functionality and utility features as well. In particular, vehicular electronic components and parts will give more challenges to automotive designers who are required to update on the latest information and knowledge associated with emerging vehicular gadgetry, particularly dashtop mobile devices, like GPS navigation, satellite radio, HD radio, mobile TV, MP3 players, video playback, and smartphone interfaces. Though not all the new vehicular gadgets are to be designated as factory standard items, some of them may be integral to determining the future course of any specific vehicular models.

|

| Draft of OScar design proposal |

Exterior design

The design teams responsible for the exterior of the vehicle develops the proportions, shape, and surface details of the vehicle. Exterior design is first done by a series of manual sketches and digital drawings. Progressively, drawings that are more detailed are executed and approved by appropriate layers of management, followed by digital rendering to images. Consumer feedback is generally sought at this point to help iteratively refine vehicle concepts according to the targeted market and will continue throughout the rest of the design refinement process. After more progressive refinement, industrial plasticine and or digital models are developed from and along with the drawings and images. The data from these models are then used to create quarter-scale and finally full-sized mock-ups of the final design. With three- and five-axis CNC milling machines, the clay model is first designed in a computer program and then "carved" using the machine and large amounts of clay. Even in times of photorealistic 3D (three dimensional) software and virtual models on power walls, the clay model is still the most important tool for a final evaluation of the exterior design of a vehicle and, therefore, is used throughout the industry.

Interior design

The designer responsible for the vehicles' interior develops the proportions, shape, placement, and surfaces for the instrument panel, seats, door trim panels, headliner, pillar trims, etc. Here the emphasis is on ergonomics and the comfort of the passengers. The procedure here is the same as with exterior design (sketch, digital model, and clay model).

Color and trim design

The color and trim (or color and materials) designer is responsible for the research, design, and development of all interior and exterior colors and materials used on a vehicle. These include paints, plastics, fabric designs, leather, grains, carpet, headliner, wood trim, and so on. Color, contrast, texture, and pattern must be carefully combined to give the vehicle a unique interior environment experience. Designers work closely with the exterior and interior designers. Designers draw inspiration from other design disciplines such as : industrial design, fashion, home furnishing, architecture, and sometimes product design. Specific research is done into global trends to design for projects two to three model years in the future. Trend boards are created from this research in order to keep track of design influences as they relate to the automotive industry. The designer then uses this information to develop themes and concepts that are then further refined and tested on the vehicle models.

|

| Autodesk AliasStudio window |

Graphic design

The design team also develops graphics for items, such as badges, decals, dials, switches, kick or tread strips, or liveries.

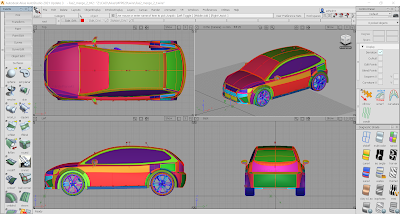

Computer-Aided Design and Class-A development

The sketches and rendering are transformed into 3D digital surface modeling and rendering for real-time evaluation with Math data in initial stages. During the development process succeeding phases will require the 3D model fully developed to meet the aesthetic requirements of a designer and well as all engineering and manufacturing requirements. The fully developed CAS digital model will be re-developed for manufacturing meeting the Class-A surface standards that involve both technical as well as aesthetics. This data will be further developed by a Product Engineering team. These modelers usually have a background in industrial design or sometimes tooling engineering in the case of some Class-A modelers. Autodesk Alias and ICEM Surf are the two most widely used software tools for Class-A development.

|

| A 1986 Ford Taurus clay model on display in Ford Detroit Styling Studio |

Development process

Design development cycle

Several manufacturers have slightly varied development cycles for designing an automobile, but in practice, these are the following :

- Design and consumer research

- Concept development sketching

- CAS (Computer Aided Styling)

- Clay modeling

- Interior buck model

- Vehicle ergonomics

- Class-A Surface Development

- Color and trim

- Vehicle graphics

The design process occurs concurrently with other product engineers who will be engineering the styling data for meeting performance, manufacturing, and safety regulations. From mid-phase, back and forth interactions between the designers and product engineers culminate into a finished product be manufacturing ready.

|

| Engine and drivetrain of a transverse-engined front-wheel drive car |

Apart from this the engineering team parallelly works in the following areas. Product Engineering (Body In White Sheetmetal Design and Plastic engineering), NVH Development team, Prototype development, Powertrain engineering, Physical Vehicle validation, Tool and Die development, and Manufacturing process design.

Development team

The design team for a specific model consists of a chief designer and an exterior as well as an interior designer. In some cases, all three roles are done by one designer. Several junior designers are involved in the development process as well who make specific contributions all overseen by the chief designer. Apart from this, the color and trim designer works closely with other designers. The clay model team and digital model team work closely with the styling team all located within the studio. Apart from this, there would be studio heads, studio managers, and prototype engineers who would work across all teams in the studio. The total team size for developing a full car usually ranges from 25 to 40 members and the development time lasts for more than 24 months until signed-off for tooling and production. Thereafter a smaller team would be working until vehicle launch.

|

| Opel Monza Concept in its early design stages |

Components

The integration of an automobile involves fitting together separate parts to form a monocoque body or units and mounting these onto a frame, the chassis. An automobile chassis basically comprises the following :

- Body shell: forms the skeleton of the vehicle.

- Engine: power train unit of the vehicle; which in the past has been in large part, the internal combustion engine.

- Transmission system: aids in transferring the drive from the engine to the wheels. Its main components are the clutch, gearbox, final drive, and differential.

- Suspension system: used to connect the wheels to the body or chassis frame.

- Steering system

- Brakes

- Electrical equipment

- Interior : dashboard, door panels, headliner, seats, etc.

The chassis is complete in itself as a road vehicle. It can drive and control itself just as in the case of a complete car and therefore, in many motor works, the chassis is usually tested on the road before the complete body of the vehicle is attached as the chassis alone can behave as the propulsion means.

No comments:

Post a Comment